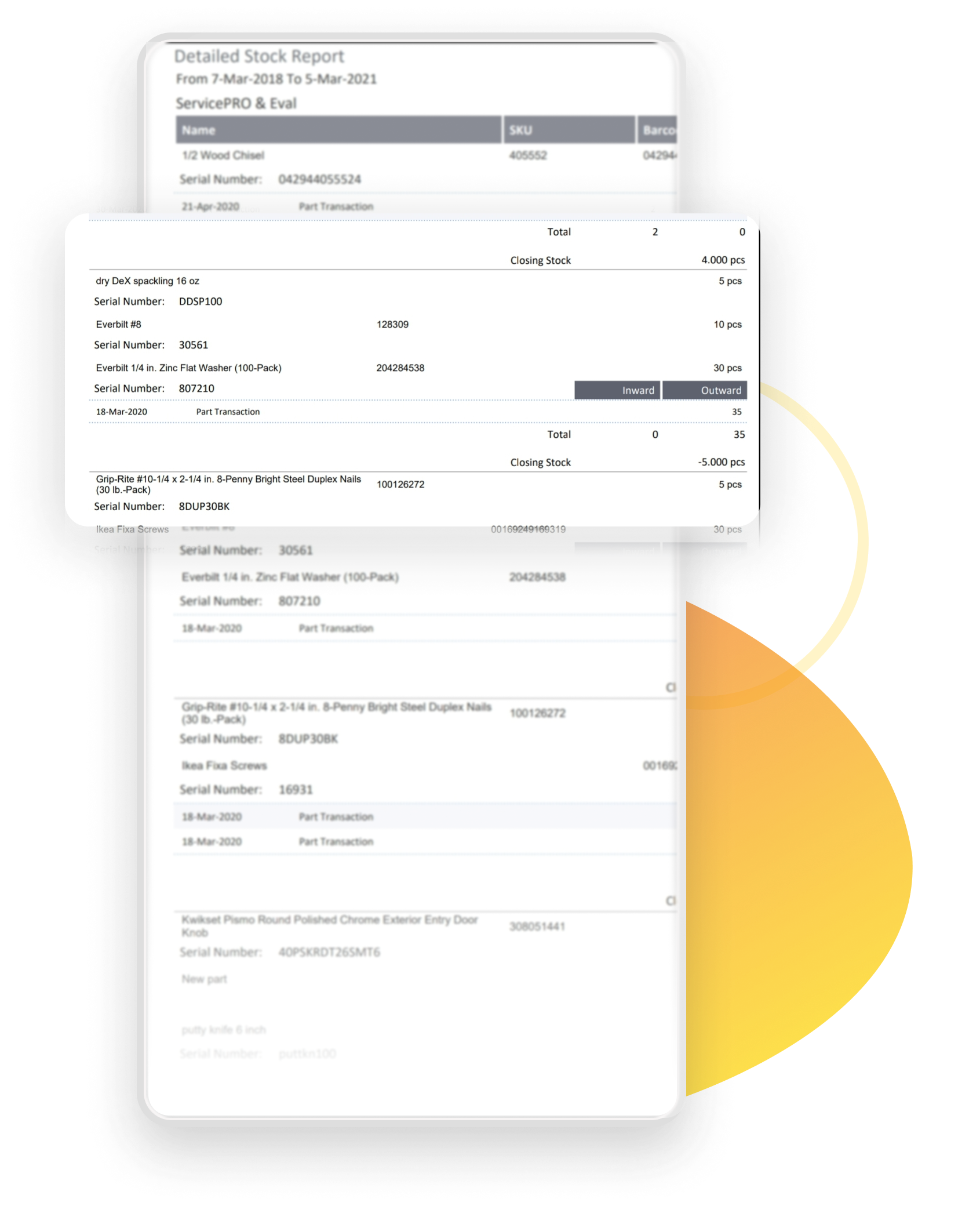

For all the parts crossing the Minimum Quantity Threshold, notifications can be sent to either Supervisors or Administrators. This can be either a real time notification or a grouped notification at a particular time of the day.

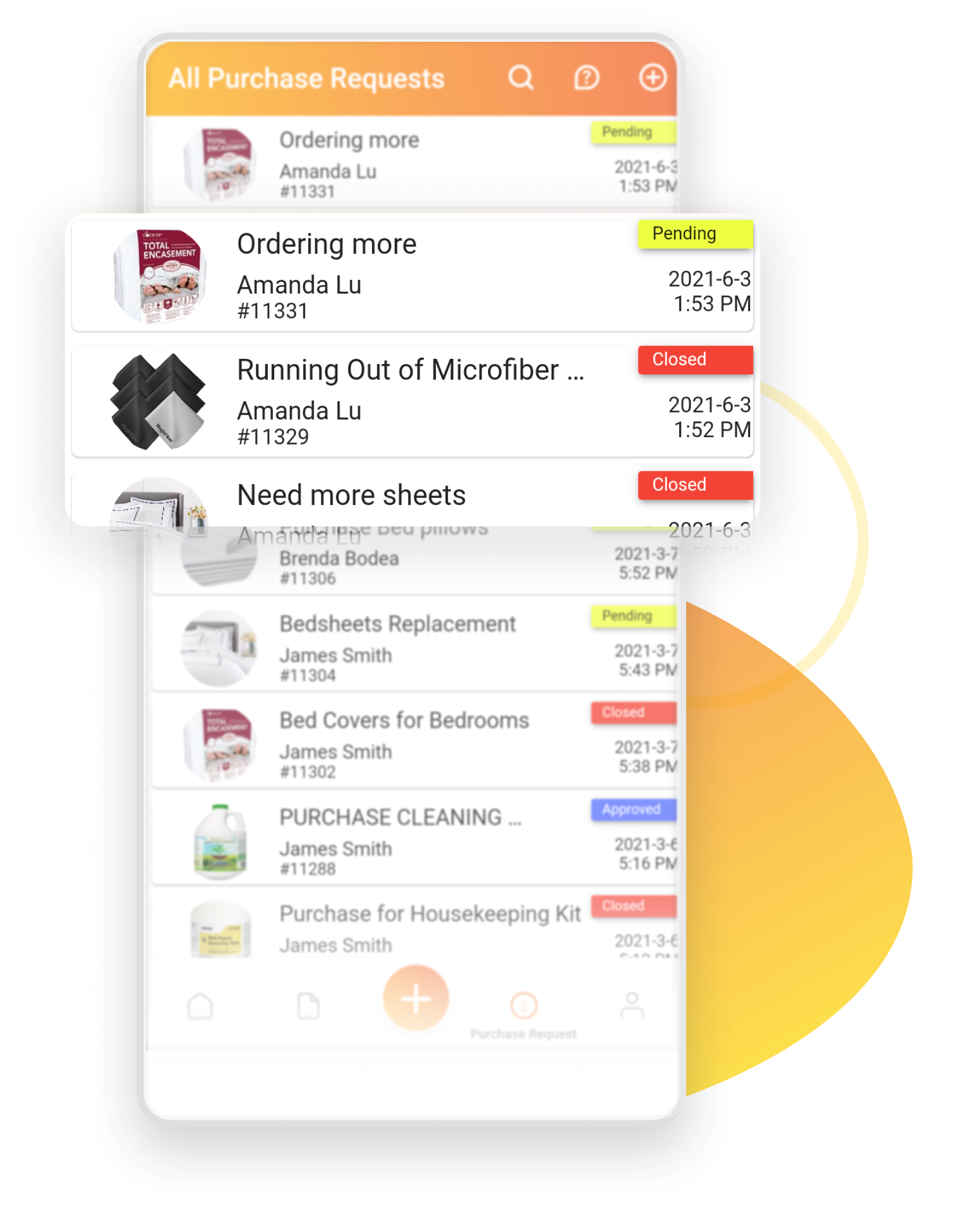

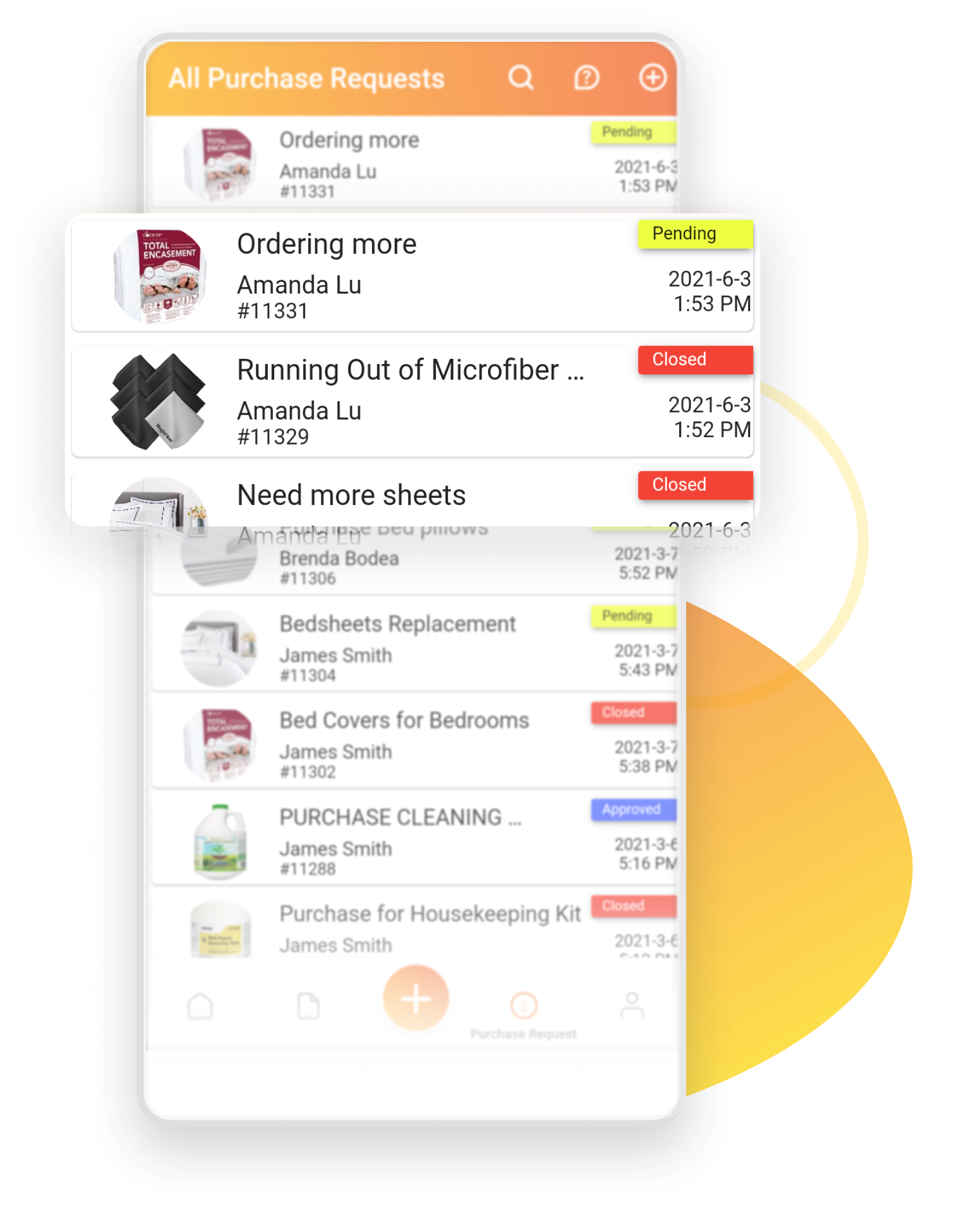

An end user, a technician or a supervisor can easily submit Purchase requests to order new parts or when parts are running low on quantity. When submitting a purchase request, the user has the ability to choose product from a catalog. Upon selecting the product name and the vendor name, unit cost of the product automatically gets populated. The supervisor then has the option to approve all the items or partially approve the items requested or reject the purchase altogether.

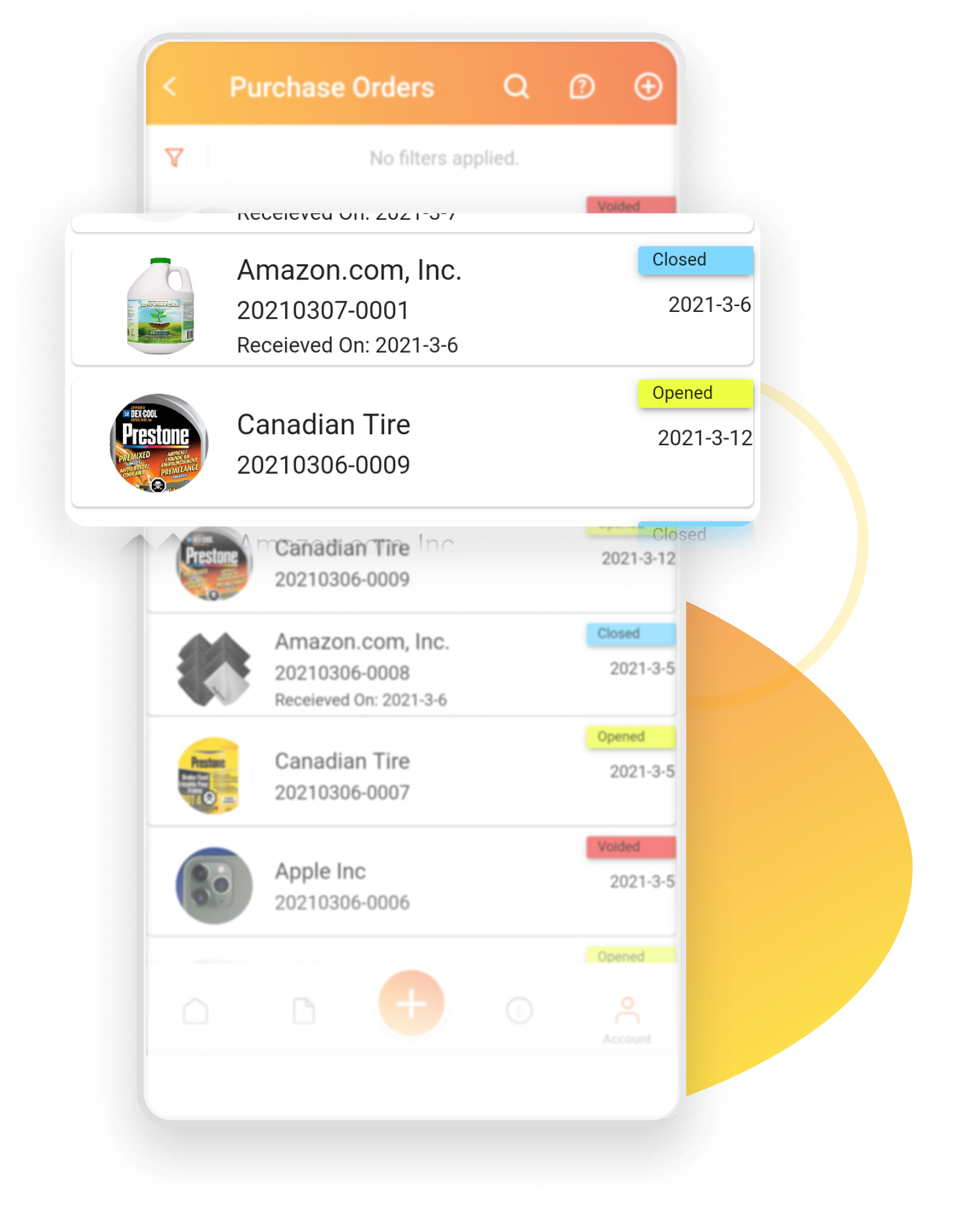

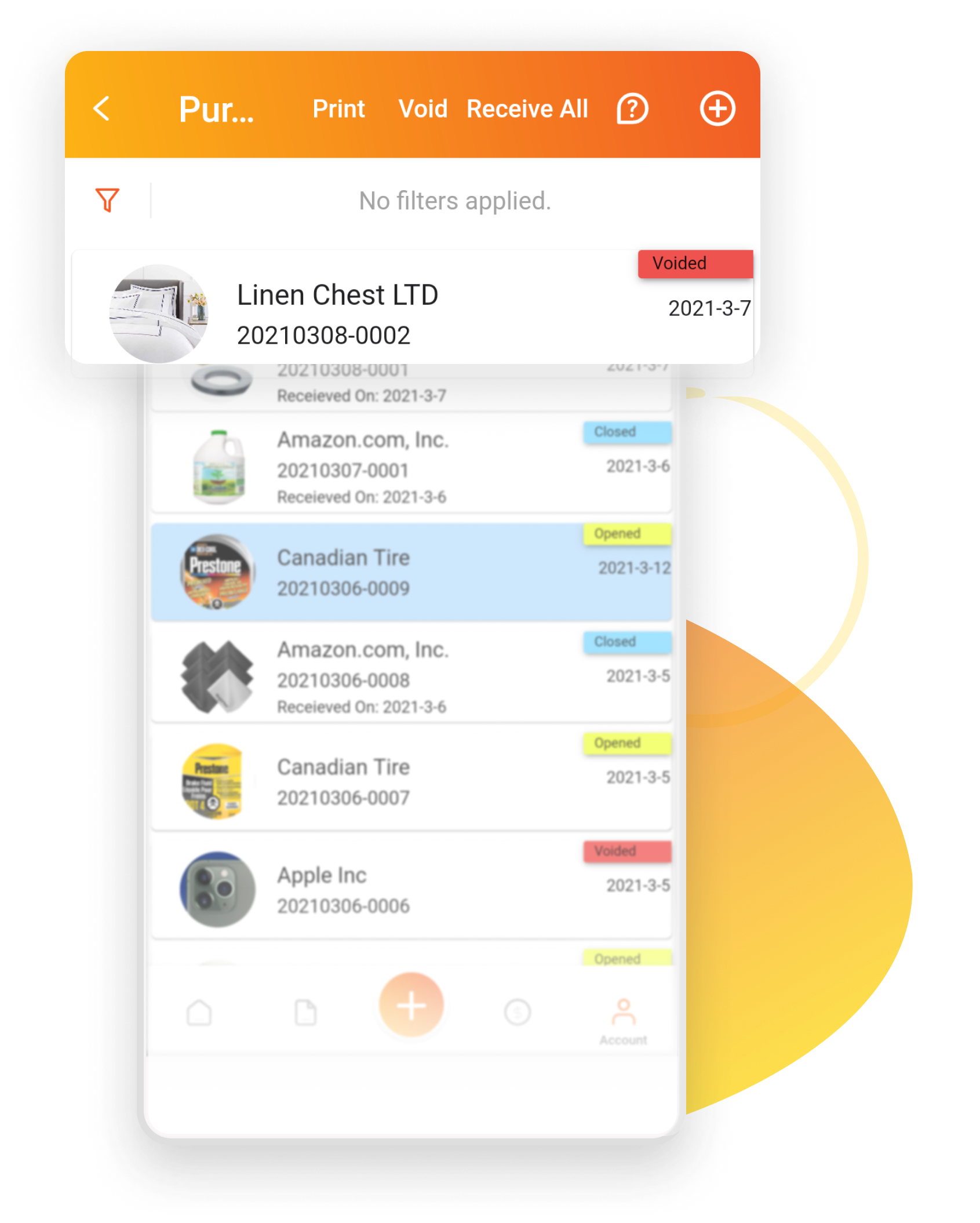

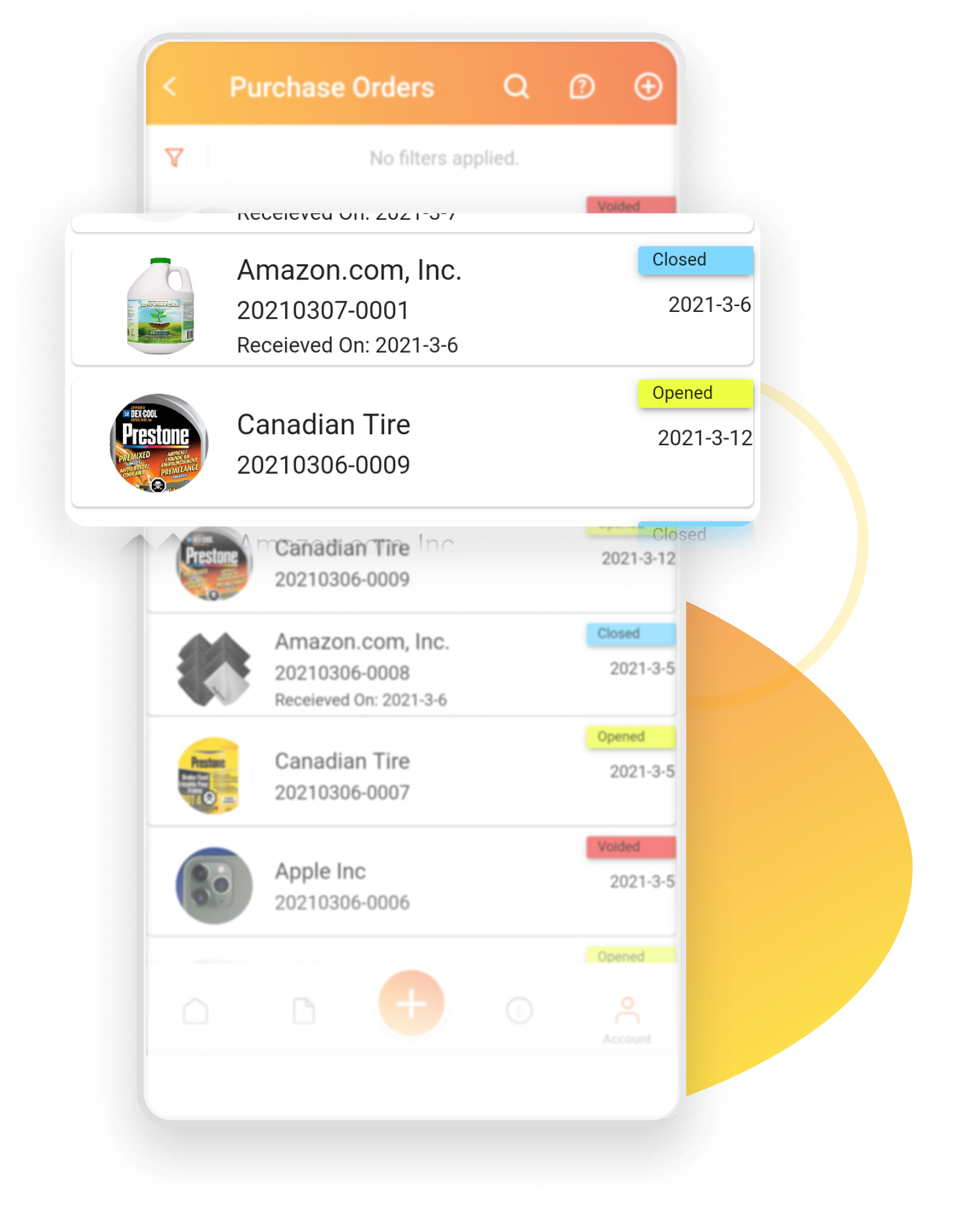

Purchase Orders allow supervisors to easily submit the orders for purchasing the items once the purchase requests are approved. Supervisors have the ability to create purchase orders on demand, review opened, closed or voided purchase orders from an organized list. Purchase Order options consists of setting the company’s shipping or billing address, mailing method and terms and conditions at the system level.

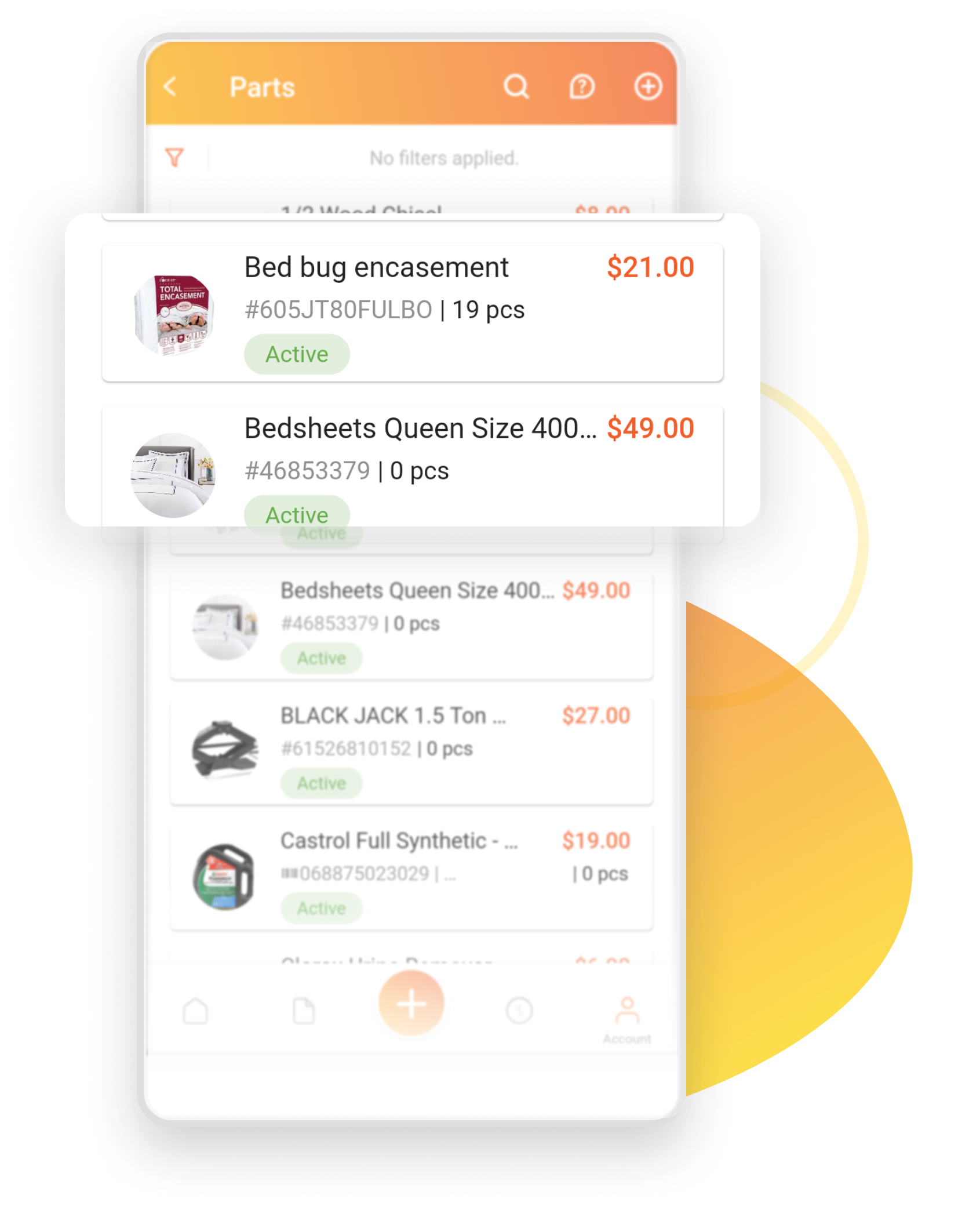

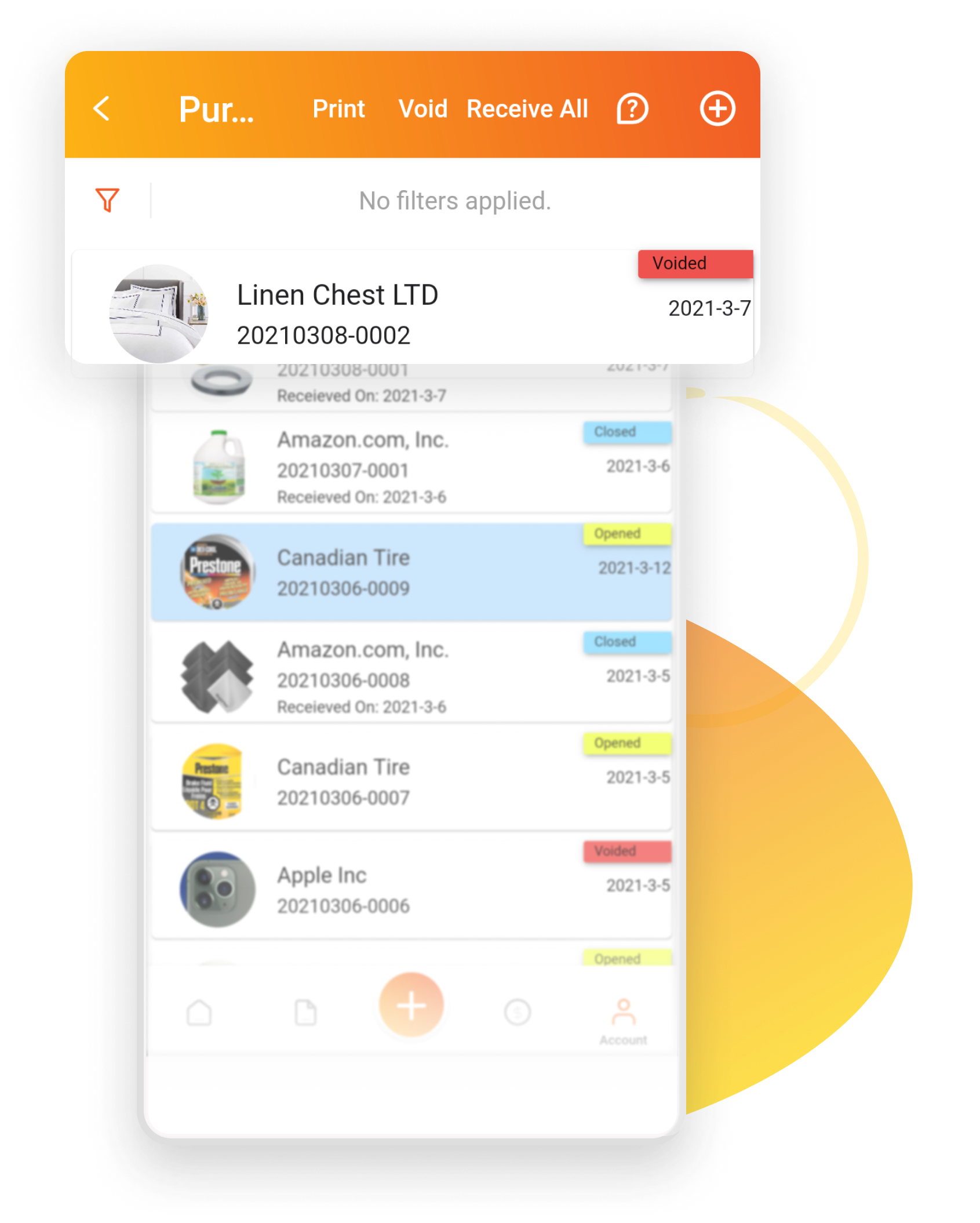

Receiving purchase orders will automatically create the parts in the system. Then these parts can be easily allocated to users, Organizational Units, companies, or assets for which they were ordered for. When all products in a Purchase Order have been received, the system will automatically close the PO to complete the process without any intervention.

An end user, a technician or a supervisor can easily submit Purchase requests to order new parts or when parts are running low on quantity. When submitting a purchase request, the user has the ability to choose product from a catalog. Upon selecting the product name and the vendor name, unit cost of the product automatically gets populated. The supervisor then has the option to approve all the items or partially approve the items requested or reject the purchase altogether.

Purchase Orders allow supervisors to easily submit the orders for purchasing the items once the purchase requests are approved. Supervisors have the ability to create purchase orders on demand, review opened, closed or voided purchase orders from an organized list. Purchase Order options consists of setting the company’s shipping or billing address, mailing method and terms and conditions at the system level.

Receiving purchase orders will automatically create the parts in the system. Then these parts can be easily allocated to users, Organizational Units, companies, or assets for which they were ordered for. When all products in a Purchase Order have been received, the system will automatically close the PO to complete the process without any intervention.