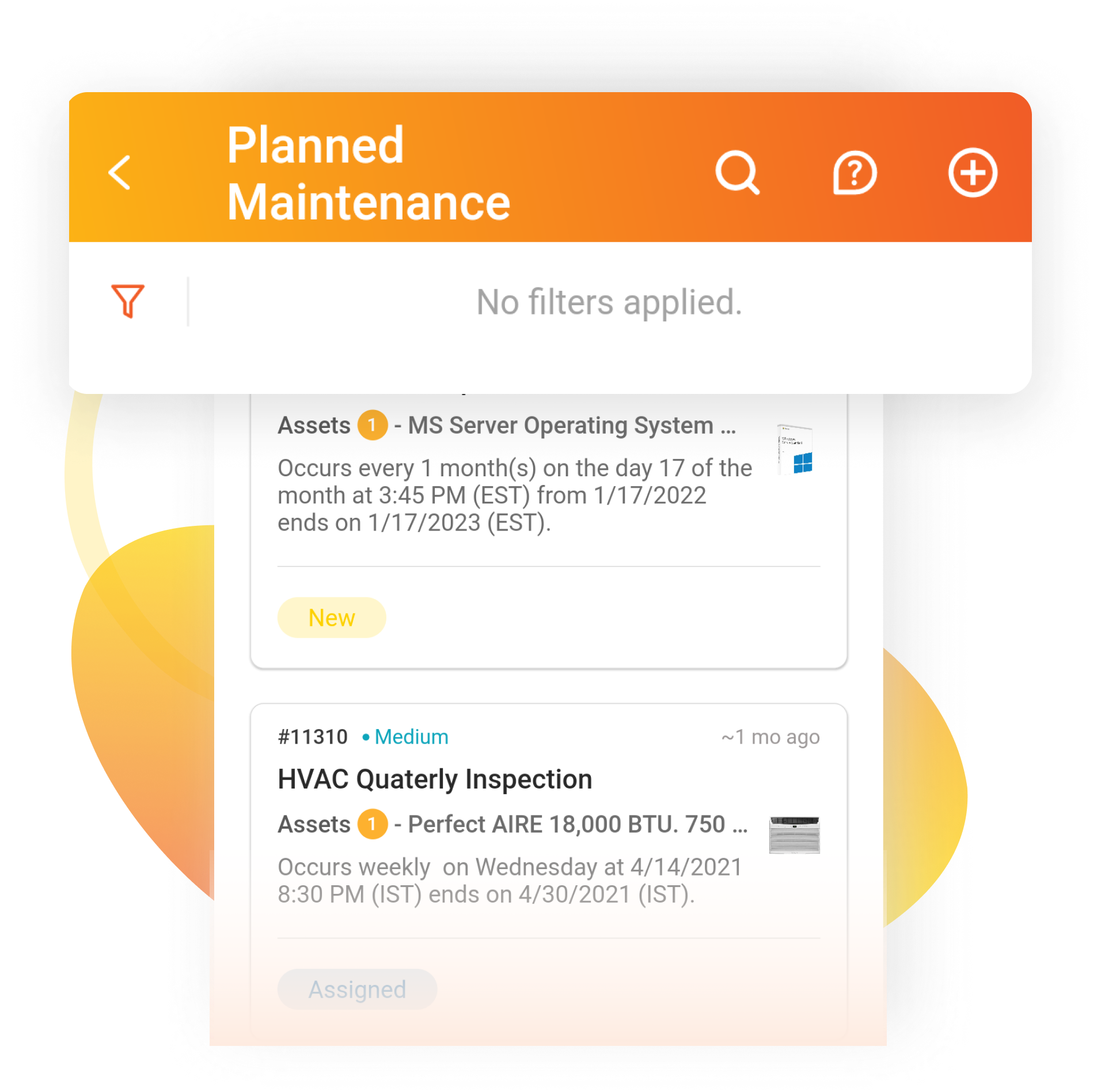

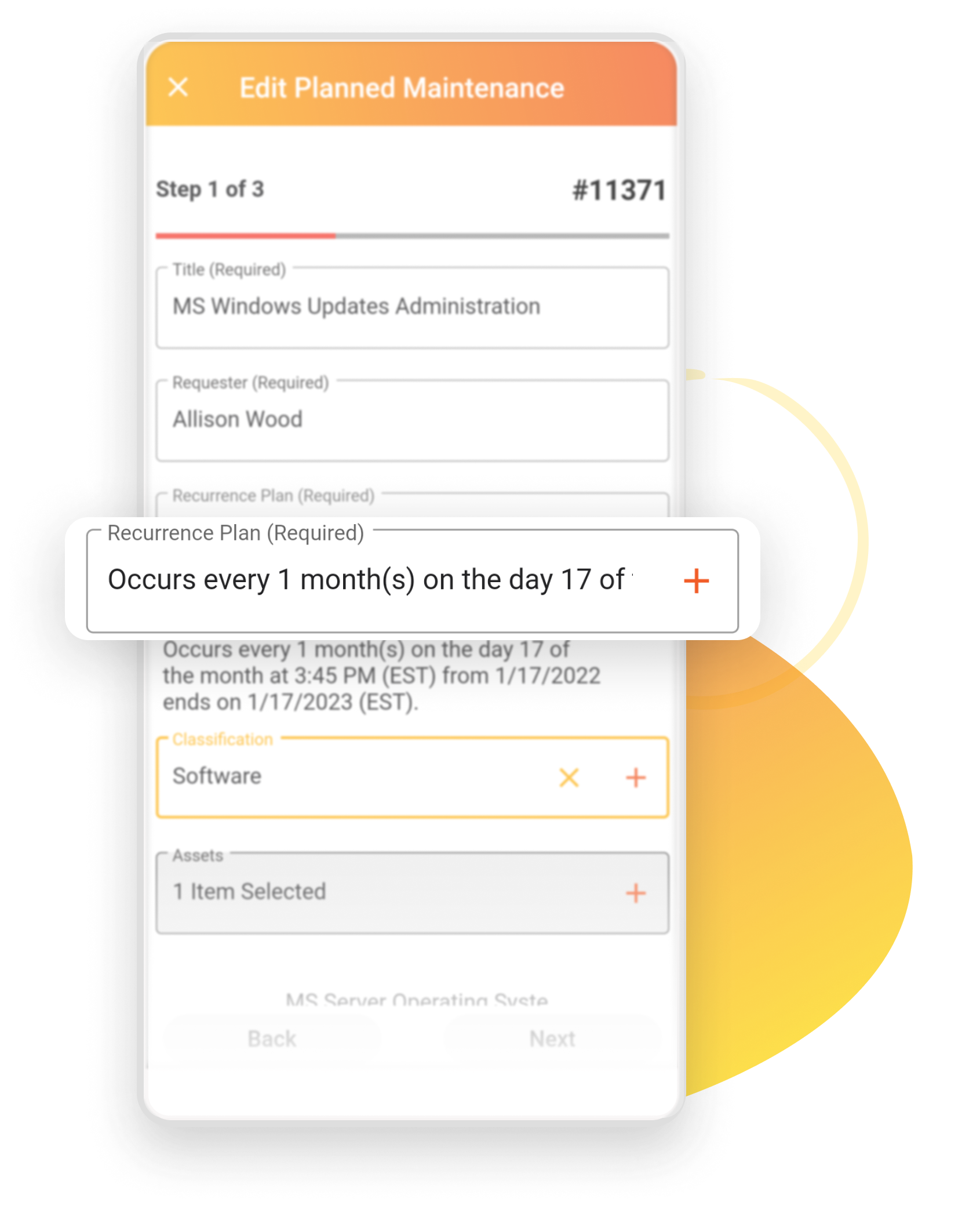

Schedule Work Orders at a specified recurrence interval to handle the Preventive maintenance for the assets in your organization.

Preventive, Planned or Proactive maintenance ensures reliability, efficiency and durability of your assets. It reduces the risk of your systems or machines failing at times of need.

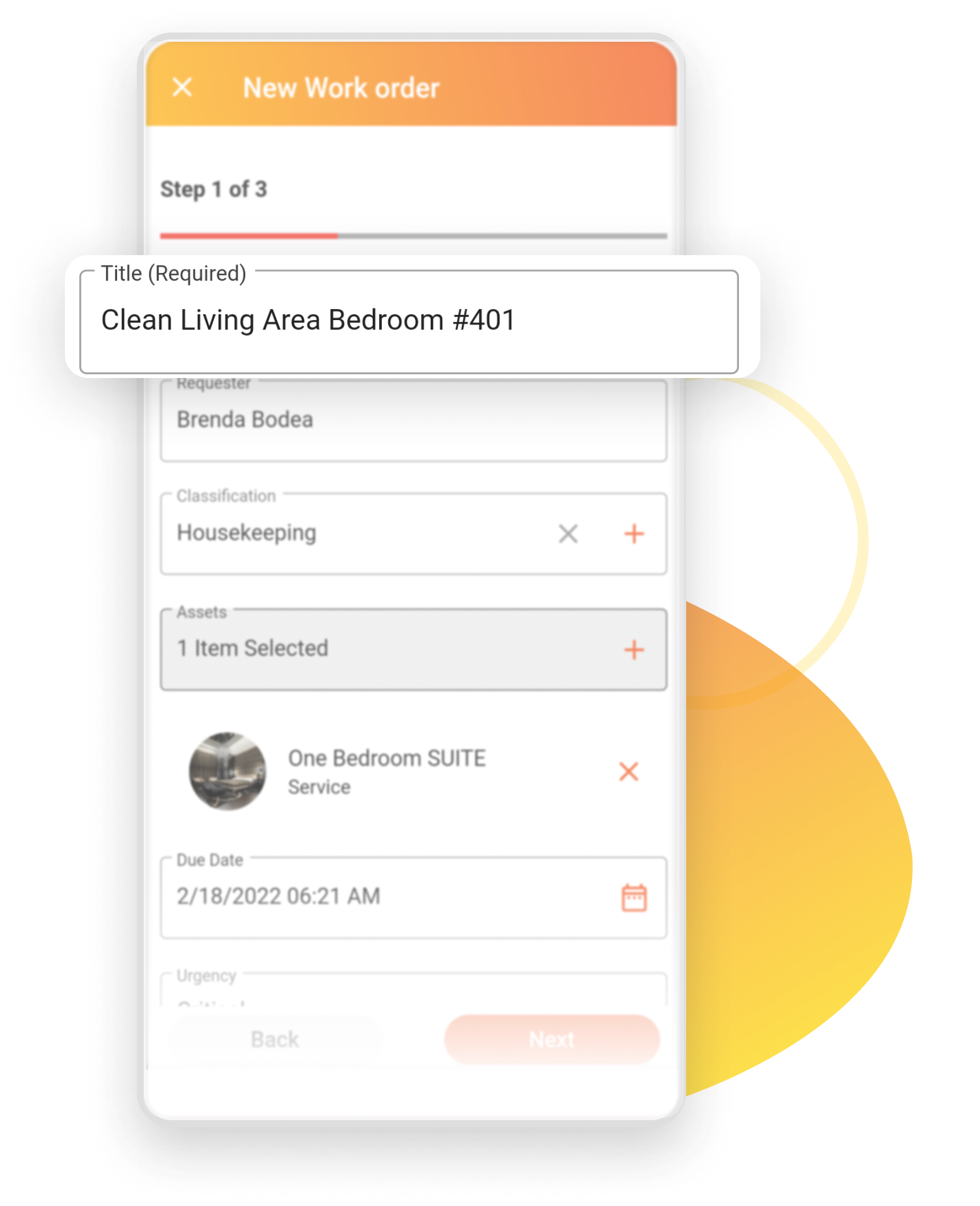

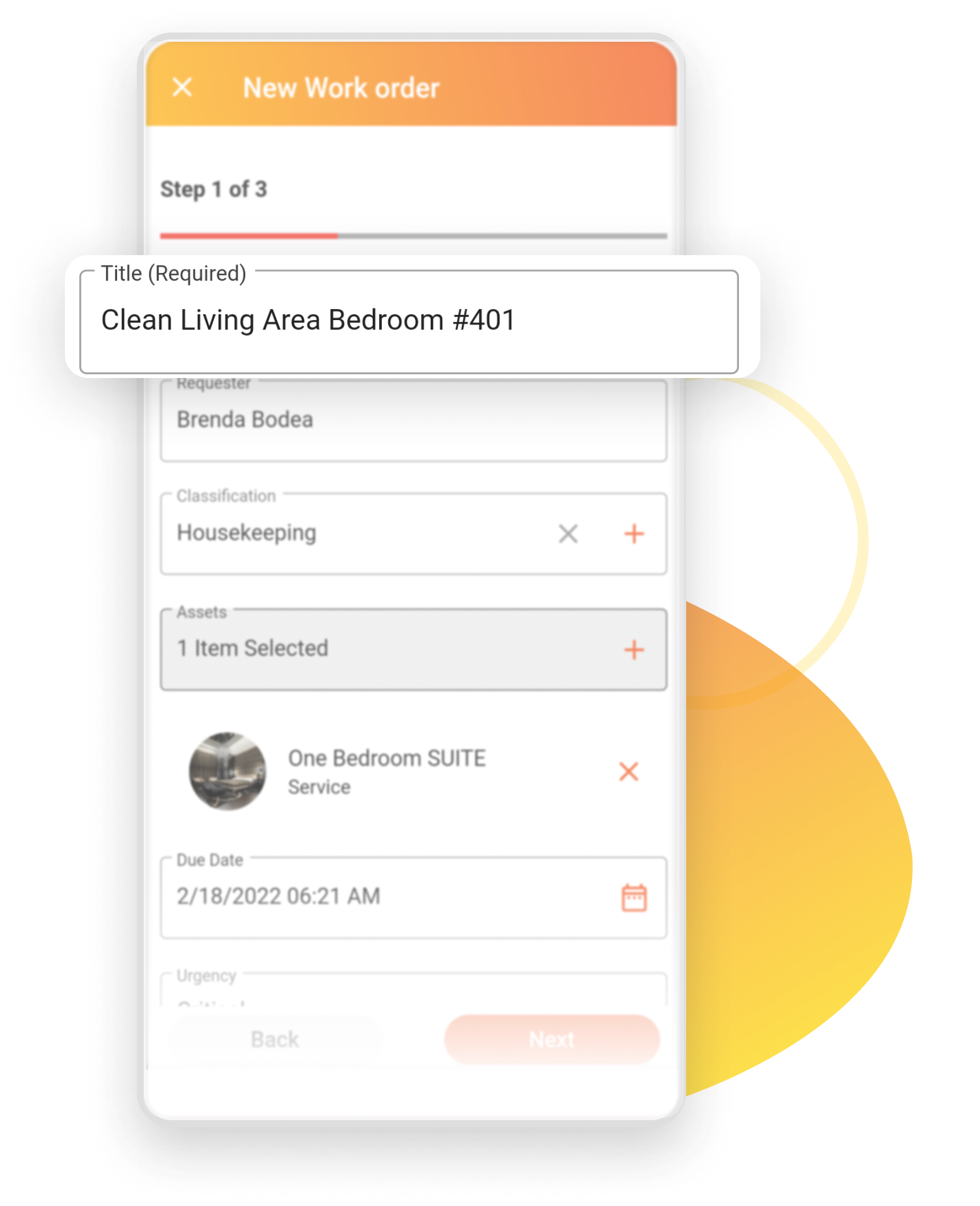

Users can submit Work Orders with specifying the urgency whenever an unexpected asset failure happens, to initiate Reactive Maintenance for the asset.

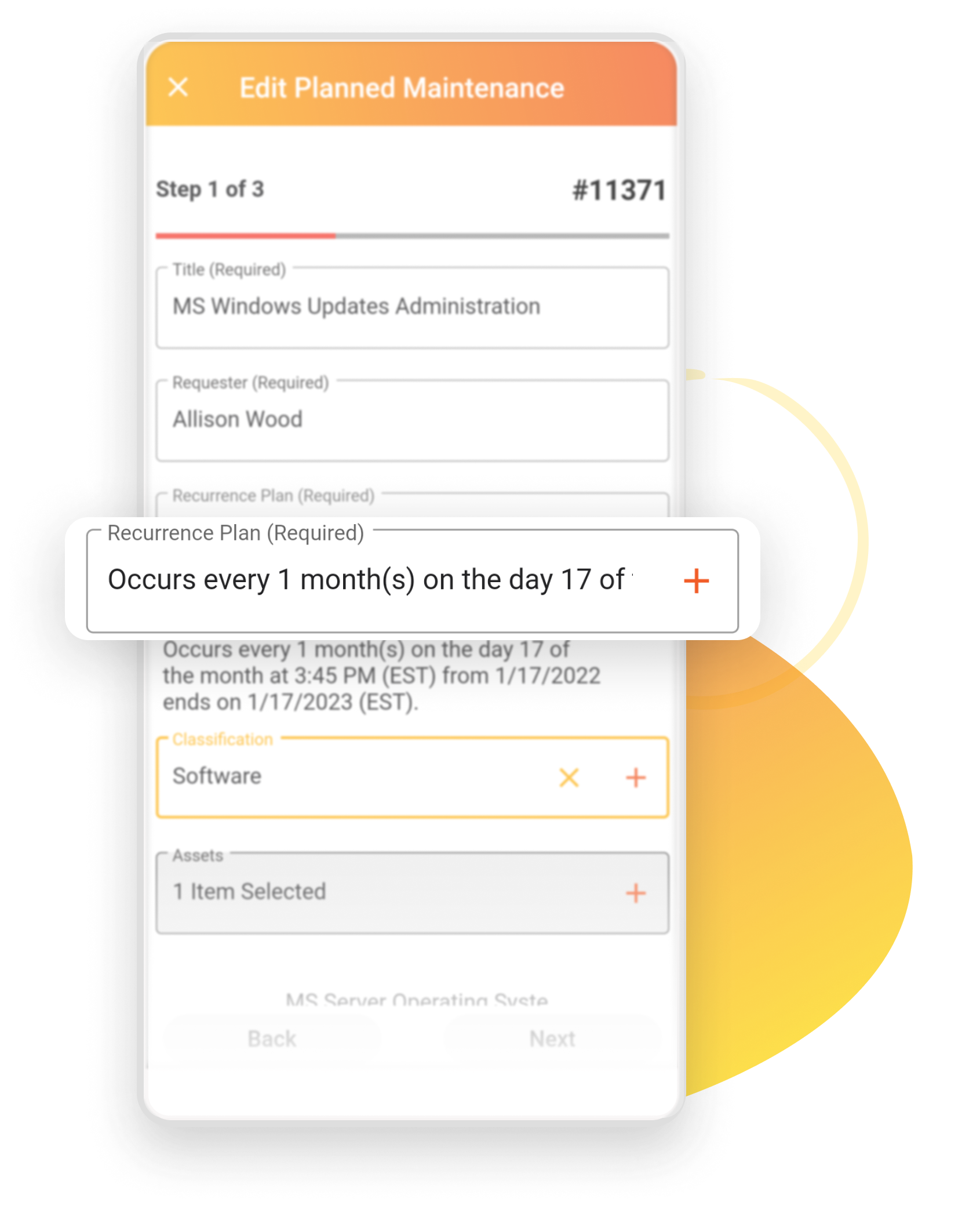

Once a schedule is associated to the master work order, then based upon the frequency that is set, Work Orders will be created on the given occurrences to complete the planned maintenance for the asset.

Any changes made to the master work order will automatically apply to all the future work orders that will be created from it.

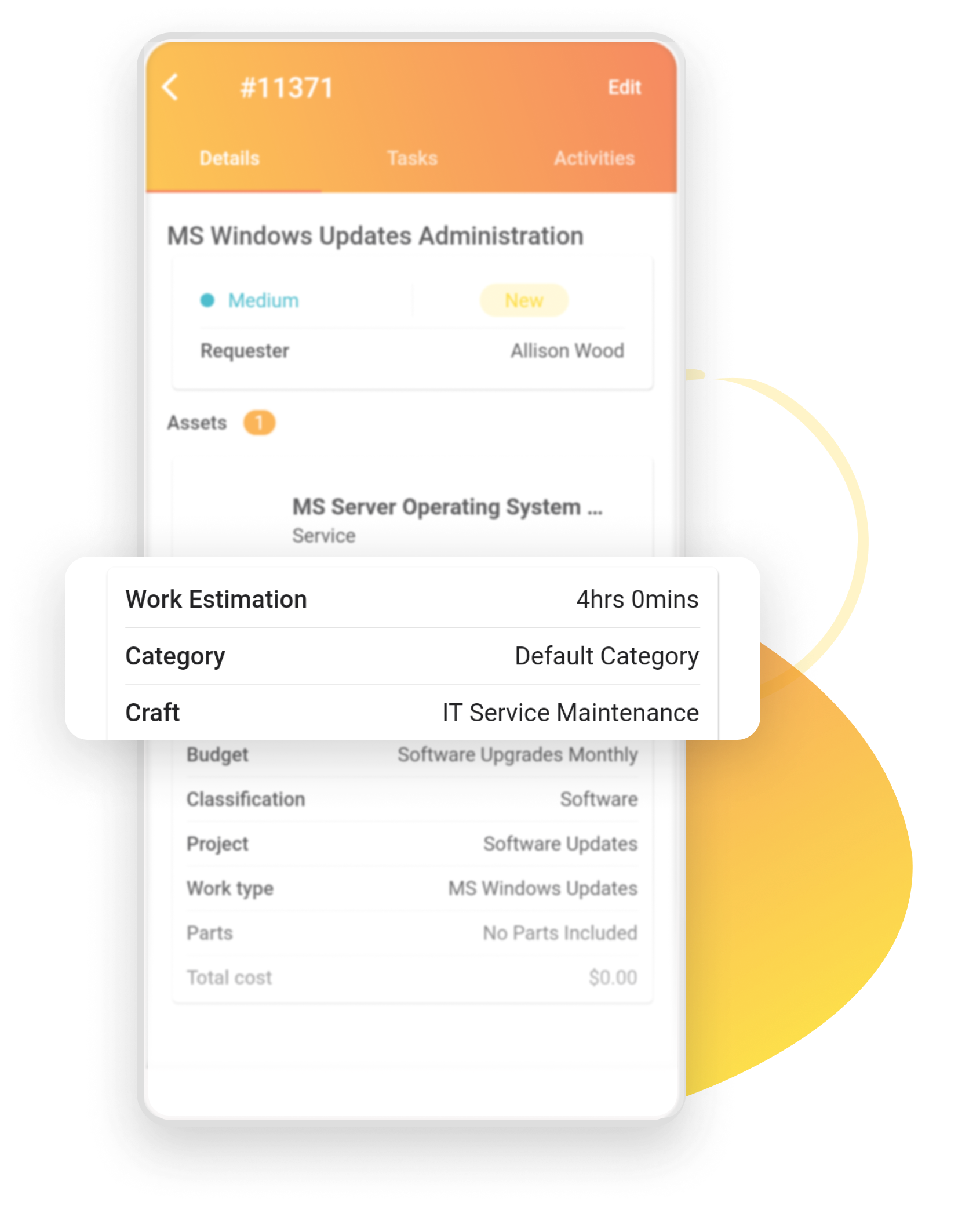

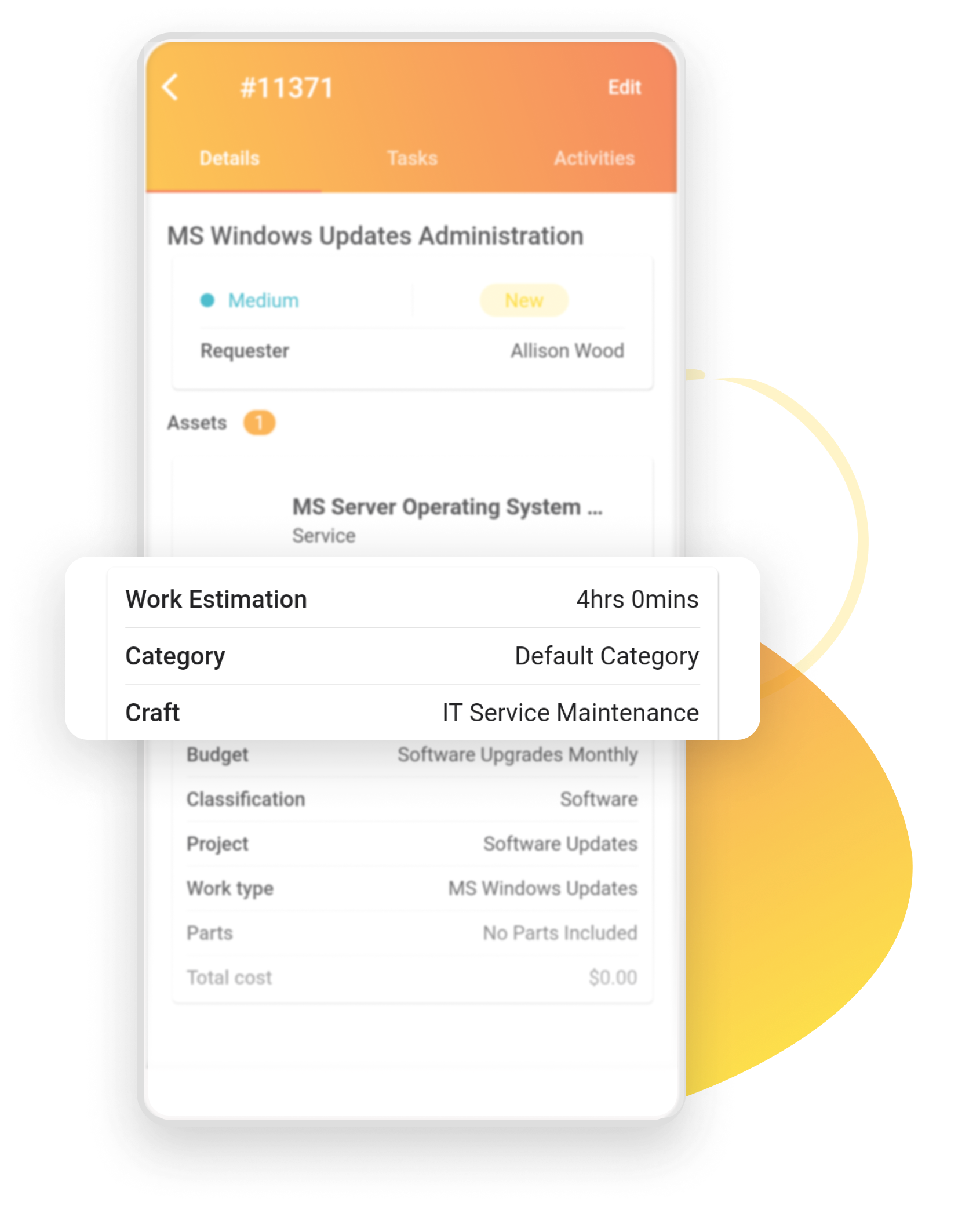

Reporting on Projected labor hours for planned maintenance is available to help the supervisor plan the necessary resources ahead of time.

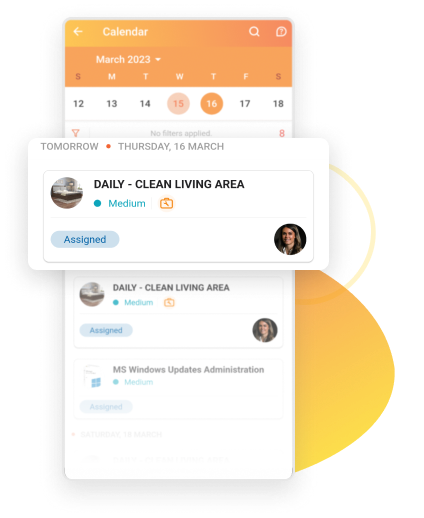

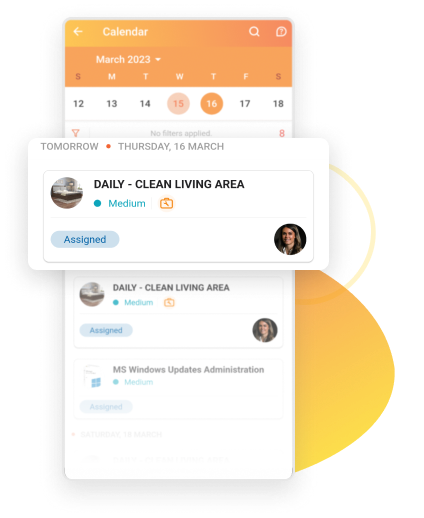

For the selected calendar date, lists the Planned Maintenance Schedules that occur on that date, and also lists the Work Orders that are created on that date.

Users can submit Work Orders with specifying the urgency whenever an unexpected asset failure happens, to initiate Reactive Maintenance for the asset.

Once a schedule is associated to the master work order, then based upon the frequency that is set, Work Orders will be created on the given occurrences to complete the planned maintenance for the asset.

Any changes made to the master work order will automatically apply to all the future work orders that will be created from it.

Reporting on Projected labor hours for planned maintenance is available to help the supervisor plan the necessary resources ahead of time.

For the selected calendar date, lists the Planned Maintenance Schedules that occur on that date, and also lists the Work Orders that are created on that date.